High Pure Graphite Thermal Pad Film/Graphite Thermal Foil/Graphene Thermal Conductive Paste for Electronics

Overview Product Description * Free sample, drawing customization available Can be arbitrarily cut according to customer

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Long-Term Temperature Resistance | 400 |

| Short-Term Temperature Resistance | 200 |

| The Thermal Conductivity | 700~1900W/M-K |

| Applicatipn | Electrical and Electronic Products Heat Dissipatio |

| Temperature Tolerance Range | -40-400 |

| Thickness | 0.025-0.1mm |

| Transport Package | by Clients′ Requirement |

| Specification | 12-100um or Custom-Made |

| Trademark | xingshi |

| Origin | China |

| Production Capacity | 5000000piece Per Month |

Product Description

Product Description

* Free sample, drawing customization available Can be arbitrarily cut according to customer size drawings

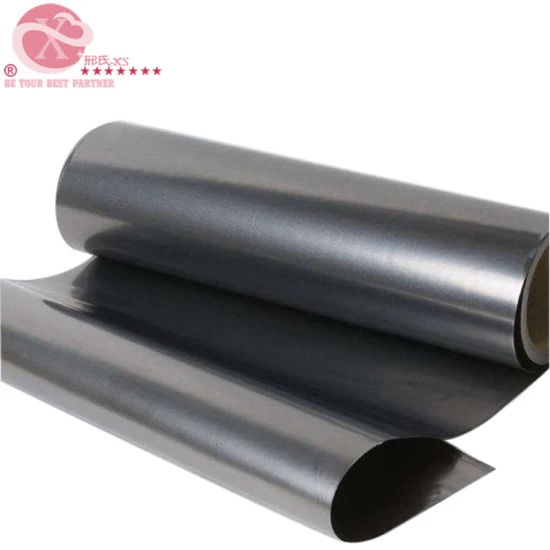

* Length & Width: custom-made Thickness: 0.025-0.1mm Normal Size: 200*400mm,300*300mm,500mm*500mm* Characteristics of graphite film:1.The surface can be combined with other materials such as metal, plastic, self-adhesive, etc. to meet more design functions and needs.2. Excellent thermal conductivity: 150~1200W/m.k, 700-1900W M.K, which is better than metal thermal conductivity.3. Light weight, the specific gravity is only 1.0~1.3, soft and easy to operate.4. Low thermal resistance, temperature resistance up to 400ºC5. The graphite heat sink can be smoothly attached to any flat and curved surface, and can be cut in any form according to customer needs

Thermal graphite sheet can be divided into natural graphite sheet and synthetic graphite sheet. As the horizontal heat conduction materials, both have high thermal conductivity, lightweight, flexible and easy to be cut. So we can offer die cut graphite sheet, graphite tape and composite graphite sheet with adhesive on both sides.

Difference between the two kinds of pyrolytic graphite sheets:

1. The natural graphite sheet, also called graphite paper, under the microscope is much rougher than the synthetic graphite sheet. While the synthetic graphite sheet, also known as artificial graphite foil has fewer impurities and higher density than the natural graphite paper.

2. As pyrolytic graphite material, the thermal conductivity of synthetic graphite sheet is 700~1900W/m-K, while that of natural graphite paper is only 150~600W/m-K.

3. Artificial graphite sheet is more complex and expensive than natural flexible graphite sheet, because artificial graphite sheet is produced during high temperature sintering process. The price and effect of natural graphite paper can be accepted and convinced by industry users, so natural graphite sheet has been widely used in various industries like Petrochemical, Refining and Power Generation industries.

Detailed Photos

Production Process

Certifications

Factory

Related Products

-

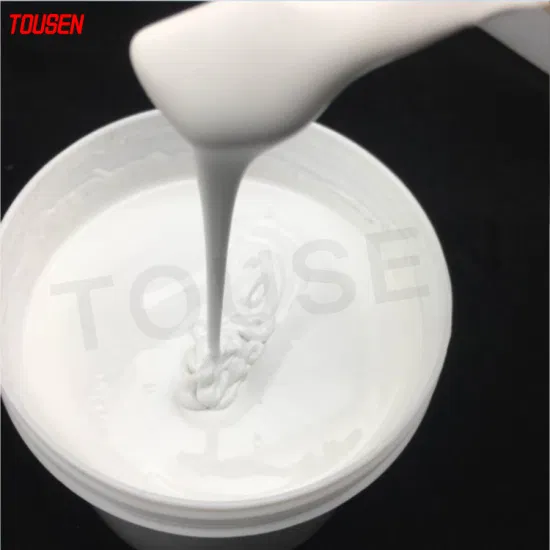

![Tousen Thermal Grease Heat Conductive Paste Thermal Paste Syringe Cooling Heat Factory Produced Wholesale RoHS Recognized]()

Tousen Thermal Grease Heat Conductive Paste Thermal Paste Syringe Cooling Heat Factory Produced Wholesale RoHS Recognized

-

![OEM ODM Customized Shielding Net Plastic Injection Products for Electrical Electric Product Accessories Parts Part Accessory Power Supply/PA+CF Material]()

OEM ODM Customized Shielding Net Plastic Injection Products for Electrical Electric Product Accessories Parts Part Accessory Power Supply/PA+CF Material

-

![Uniform Black Shielding Material for Thermoplastic Non]()

Uniform Black Shielding Material for Thermoplastic Non

-

![Thermal Interface Material Thermal Pads Thermal Heating Pads Low Thermal Resistance Wholesale Customized Cooling Thermal Mat Gap Filling Materials]()

Thermal Interface Material Thermal Pads Thermal Heating Pads Low Thermal Resistance Wholesale Customized Cooling Thermal Mat Gap Filling Materials