Thermally Conductive Graphite Thermal Paste High Condutivity Thermal Paste GPU

Overview thermally conductive graphite thermal paste high condutivity thermal paste gpu Company Profile Guangdong Dongse

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Thermal Conductivity | 1.0-8.0W/M-K |

| Transport Package | Custom |

| Specification | 1g, 3g, 7g, 15g, 30g 1kgs, custom |

| Trademark | TOUSEN |

| Origin | China |

| HS Code | 35069190 |

| Production Capacity | 500t |

Product Description

thermally conductive graphite thermal paste high condutivity thermal paste gpu

Company Profile

Guangdong Dongsen Zhichuang Technology Co., Ltd. was established in 2009 with a total registered capital of 11 million Chinese Yuan and more than 200 employees. We have two independent manufactuers located in Huizhou and Jiangxi separately . we also have oversea offices in HK and Japan to provide high-quality services to all our valued customers. Our company has passed ISO 9001, ISO1400, IATF16949, OHSAS18001 and other related management system certifications, and our products have got UL\CE\ROHS\REACH and other certifications. As a professional manufacturer in the field of thermal interface materials and EMI electromagnetic interference materials, Dongsen mainly provides silicone thermal conductive pads, thermal grease, thermal graphite sheet , thermal conductive tape rolls ,metal foil tapes (copper foil tape, aluminum foil tape), high temperature polyimide tapes, also we provide die cutting customize service as per customers' drawings. We are one of the biggest and most comprehensive solution suppliers of thermal conductivity materials, insulating materials and shielding materials in China. Dongsen focuses on meeting customer needs and strives to maximize the profits of customers. We gain trust of various well-known customers, and has long-term cooperation with Samsung, ZTE, Changhong, Panasonic, Foxconn, Midea, etc., and has been well received!

Our Partners

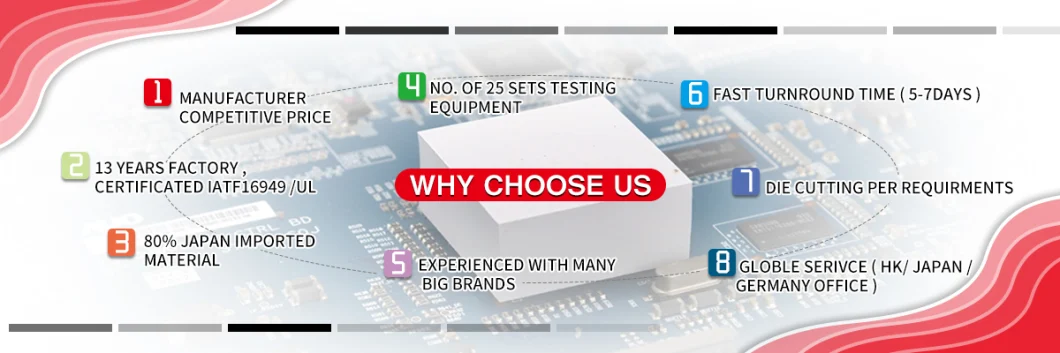

Our Advantages

THERMAL COMPOUNDS

We are engaged in offering a wide range of Thermal Compounds that are manufactured using state-of-the-art technology and latest machinery. They are silicone fluids based on silicone, adding filler, thermal conductivity materials, and other polymer materials, with good thermal conductivity, electrical insulation, and are widely used in electronic components. Stringently formulated using optimum quality ingredients, these are formulated in accordance with set industry standards. The range will not harden or dry out or melt even after 1000 hours 200ºCwith good single component modified silicone system suitable for heat sink application. Due to use of cost efficient technology in our assembly unit, we can supply our complete range to the customers at market leading prices. Our expertise allows us to offer a comprehensive range of Thermal Compounds, which is developed in tandem with the international quality standards. Customer satisfaction is of prime importance at this field enterprise and so supreme quality raw materials are used for manufacturing the products. They insulate the hot surface, ensuring energy conservation, protection of operators and providing comfortable work environment. Owing to their features like impeccable quality, easy to use and longer life these are highly appreciated by our clients throughout the world. We devise our range with most modern state of the art facilities and our expertise also allows us to empower them with unmatchable uncompromising quality & outstanding services.

Detailed Photos

| Model | Unit | TSG010 | TSG020 | TSG030 | TSG040 | TSG050 | TSG060 | Test Method |

| Thermal conductivity | W/M.K | 1.0 | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | ASTM D5470 |

| Thrmal impedance | ºCin/W | 0.15 | 0.1 | 0.65 | 0.055 | 0.05 | 0.032 | ASTM D527 |

| Volume impedance | Ωcm | 1.0*10^13 | ASTM D792 | |||||

| Specifica Gravity | g/cm3 | 2.2 | 2.3 | 2.6 | 2.9 | 3.2 | 3.4 | RVF#7 |

| Viscosity K cps @.25ºC | 1000 | 1800 | 1800 | 2300 | 2300 | 3500 | ASTM G166 | |

| Work. Temperature | ºC | -40-200 | 0.15 | ASTM E595 | ||||

| Valatile Conent | % | <0.25 | <0.23 | <0.2 | <0.18 | <0.15 | <0.1 | GC-FID |

High thermal conductivity thermal greaseLow oil yield, low volatility, high reliability, thinner thickness. It can fullywettability transfer interface of heat, eliminate the air gap between the formation of interface, forming effectively heattransfer path, which can quickly will transfer to the radiating heat device , and thermal conduction excellent effect .

Features:1.High thermal conductivity, insulation and low temperature performance, high stability and good use.

2.Water resistance, not curing, metal material on contact without corrosion (copper, aluminum, steel).

3.Volatilization loss, low melting, not dry, not good material adaptability and large temperature range of use ( -50-250ºC ).

4.Non-toxic, tasteless, no corrosion, and chemical and physical properties of stability.

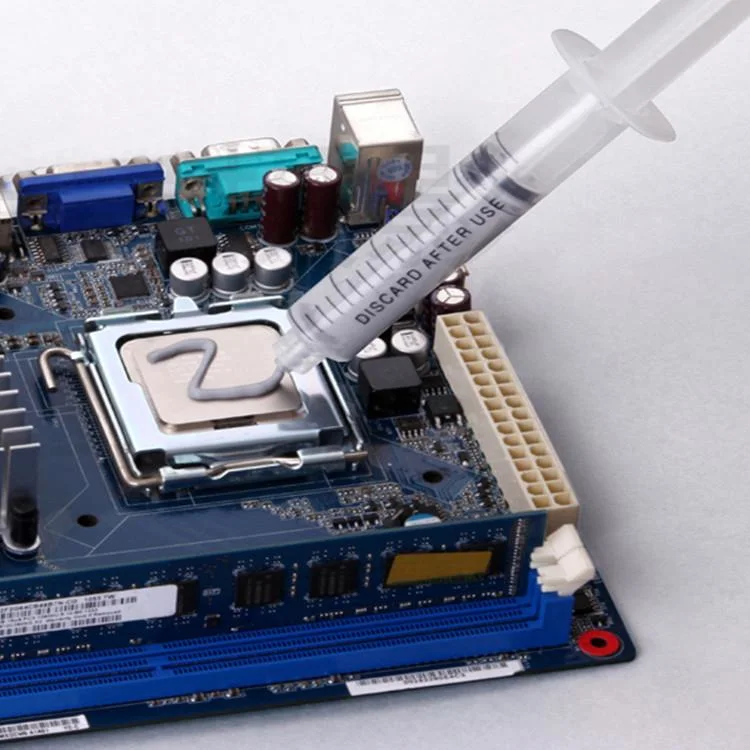

Appilcation:1.Power supply.2.Between a CPU and a heat spreader.3.Used between a semiconductor and heat sink.4.Areas where heat needs to be transferred.5. Thermoelectric cooling device.6. frame or other type of heat spreader.

Related Products

-

![Wbg Thermal Grease CPU Heatsink Compound White Thermal Conductive Paste for Processor/PS4/Laptop]()

Wbg Thermal Grease CPU Heatsink Compound White Thermal Conductive Paste for Processor/PS4/Laptop

-

![Large]()

Large

-

![Thermal Interface Material Thermal Pads Thermal Heating Pads Gap Filling Materials Low Thermal Resistance Cooling Thermal Mat Wholesale Customized]()

Thermal Interface Material Thermal Pads Thermal Heating Pads Gap Filling Materials Low Thermal Resistance Cooling Thermal Mat Wholesale Customized

-

![Thermal Interface Material Thermal Pads Thermal Heating Pads Low Thermal Resistance Wholesale Customized Cooling Thermal Mat Gap Filling Materials]()

Thermal Interface Material Thermal Pads Thermal Heating Pads Low Thermal Resistance Wholesale Customized Cooling Thermal Mat Gap Filling Materials